Kimla Storesystem automated loading and unloading system. The device was created to maximize the efficiency of laser cutting machines. The Storage system design consists of a rack in which sheet metal sheets are stored, a system that collects a sheet from the shelf and transports it to the cutting table and a system that collects cut parts and puts them on selected shelves on the tower. The compact design of Kimla Storesystem allows for the extension of subsequent storage racks. Storesystem in conjunction with the Kimla laser works in an automatic way, eliminating the need for human labor...

The innovative, proprietary three-pallet system enables the use of fast fiber lasers without unnecessary waste of time for reloading the cut materials. During laser operation, the operator has the option, in addition to the automated cycle of reloading of the cut sheet metal sheets, also to manually load and unload elements from the third pallet.

A special type of palette, used in the Kimla fiber laser, with an additional steering axis. It allows for cutting out shapes and cutting pipes with diameters up to 200 mm. The maximum tube length depends on the laser model (3,000 mm for the LF1530). The pipe to be cut rests freely during the cutting process, with no system of grips that block the possibility of cutting at the pipe ends. Thanks to this, it can be cut without unnecessary waste.

The touch scanning head is used e.g. to scan details in order to make duplicates or enter into the computer memory for further processing. The optional scanning head is an indispensable equipment of the machine for more demanding projects. The measuring probe placed on the laser gate will automatically scan the finished detail and duplicate it, which will significantly reduce the time of project preparation. This scanner is simply irreplaceable when duplicating projects with very complex shapes.

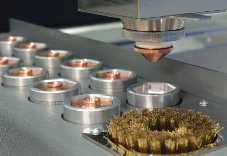

The optional nozzle magazine makes it easy to store all the nozzles needed to work with various sheets, and the automatic replacement of the nozzle and its cleaning significantly improves the process of preparing the laser for cutting.

The automatically lowered marking head allows for quick signing of sheets before cutting them, so that the subsequent identification of details automatically placed on the sheet by integrated nesting is not a problem. The print head marks details with an ink that can be easily cleaned afterwards without leaving any trace of the marking.